Barrel Washer

An extensive range of auger-based barrel washing systems are available in mild steel and stainless steel with full water recycling systems capable of cleaning up to 50tph.

-

Barrel specification to customers requirement

-

Elevator at 26°angle with Blue PVC ‘Doorstop’ belt. (Can be easily slid out of washer by releasing 2 bolts)

Read More

Bulk Bin

-

Heavy duty support chassis

-

900mm wide load bearing double sealed base track

-

Automatic filling sequence

-

Gentle feed via auto rise and fall conveyor with probe control

-

Electric variable speed unloading

-

Part empty and refill as standard

Read More

Coil Cleaner Plus

The Coil Cleaner Plus spiral cleaner moves the crop continuously, separating loose soil, clods and small potatoes from the main crop.

-

Gentle cleaning for delicate crop surfaces

-

Ultimate flexibility with split drive system

-

Simple easy adjustment mechanism

-

Highly effective cleaning action

-

Interchangeable modular design

Read More

Cyclone De-stoner

The most effective stone and clod removal for long roots

-

Mild or stainless-steel construction

-

Variable speed panel

-

Folded rubber top to paddles

-

2M or 3M diameter cyclone cone

-

Heavy duty Hywall stone elevator

-

Excellent maintenance access with minimal moving parts

-

Powerful solids handling pump

Read More

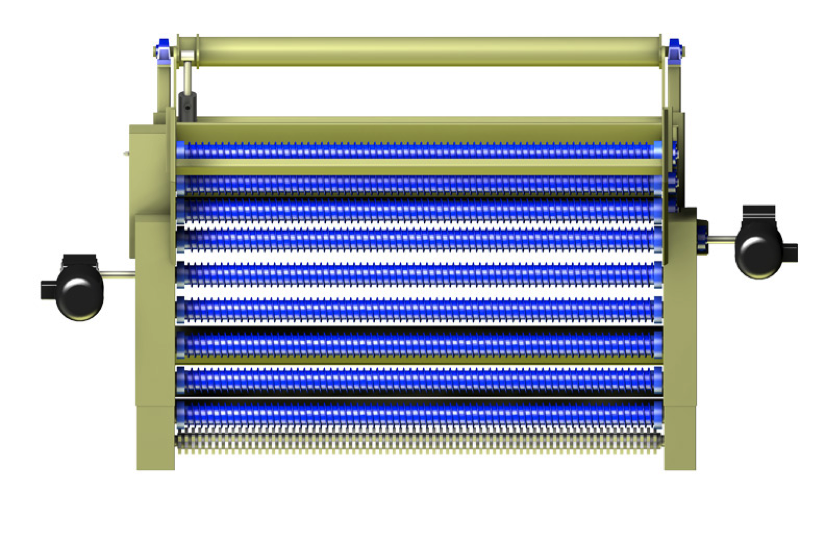

Direct Drive Roller Drier

Effective for removing surface moisture from produce

-

Wrapped felt or sponge disc roller options

-

Direct drive to each roller with no chains or sprockets, reduces overall maintenance

-

Catchment tank for waste water and debris

-

Soft start system for all rollers with motors wired to a central control panel

Read More

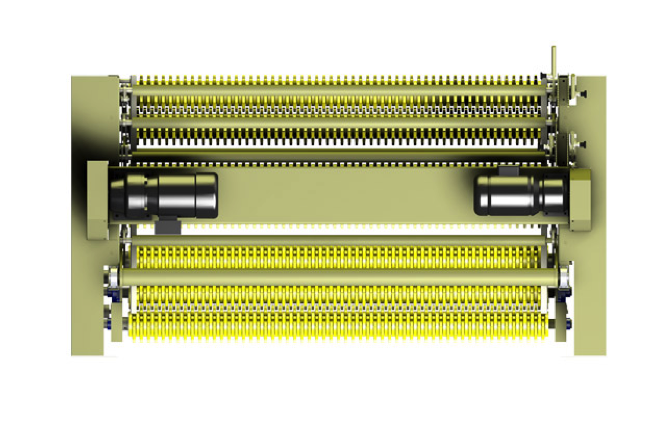

Dry Brush Unit

-

Electronic variable speed drive

-

Simple single chain drive system

-

Adjustable top rubber flaps to retain the crop on the brushes

-

Hard wearing bristle brushes

-

Hydraulic hand pump adjustment

-

Available in 13 or 21 row

-

600mm, 900mm, 1200mm or 1800mm widths

-

Driven top brushes to increase cleaning action

-

Stainless steel construction

Read More

Evenflow Hopper

Storage bin for washed or dirty produce

-

Holding capacities from 300kg

-

Continuous flow of product

-

Prevents unnecessary stopping and starting of lines

-

Gentle method of accumulating crop either in line or prior to packaging machinery

-

Available in a range of widths and lengths to suit specific applications

-

Optional variable speed drive using inverter control

-

Full stainless steel option available

-

Gentle low drop indeed and outfeed

-

Goose neck option for feeding box filler

Read More

Freestanding De-stoner

Effective stone removal with minimal water usage

-

Integrated tank for stand-alone operation

-

High capacity solids handling pump

-

Rubber chevron stone elevator belt

-

Simple set-up and operation

-

Forklift tubes for easy positioning

-

900mm or 1800mm wide indeed chute options

-

Quick release door gives cleaning/access to base of elevator

-

Optional full stainless steel construction

Read More

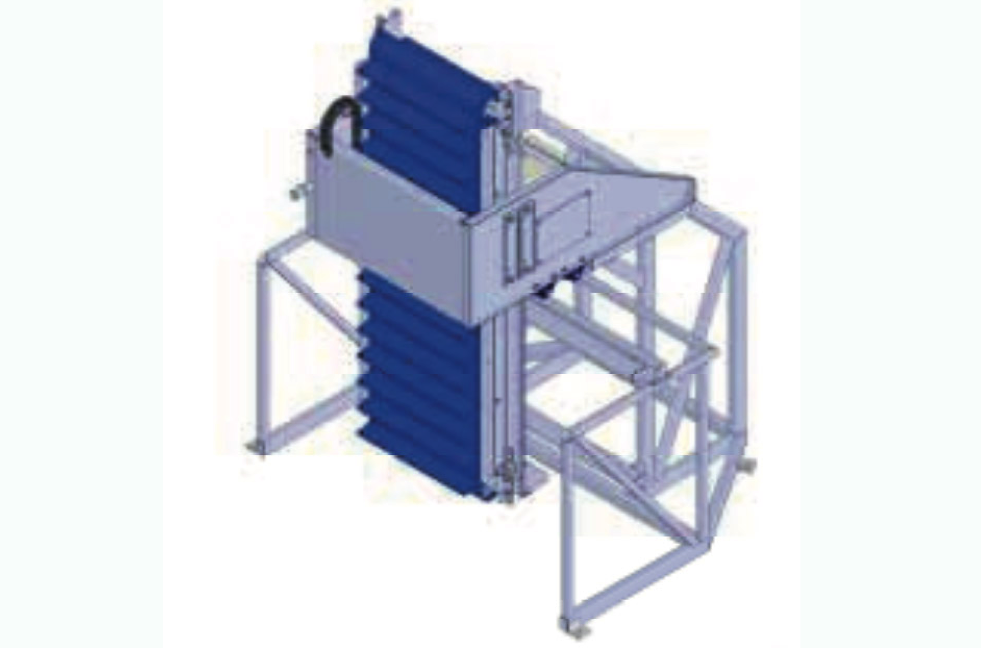

Gentle Flow Box Tipper

Single box tipping system with corner pivot low drop discharge

-

145° rotation to give max. emptying of boxes

-

Manually adjustable outfeed door

-

Gentle controlled flow emptying using probe control

-

Fully automated tipping sequence

-

Category 4 safety beam curtain

-

Standard unit capable of handling up to 1.1m high boxes

-

Space saving design, small and robust

-

Specialist models available on request (i.e. 2 tonne boxes)

-

Full stainless construction

-

Delivery belt/holding hopper

-

Automatic outfeed door

Read More

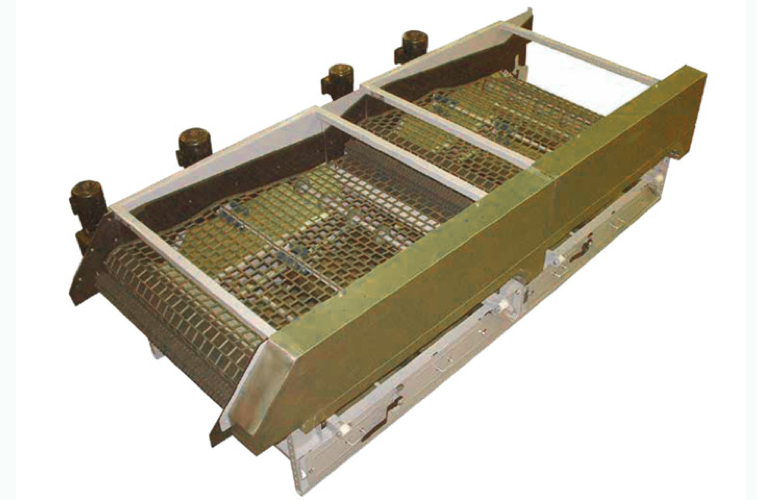

Grader Module

-

Suitable for potatoes, onions, beet and bulbs

-

Triple short throw agitators

-

High capacity accurate crop grading

-

Well proven design and robust construction

-

“Push and Pull” drive mechanism

-

Simple screen tensioning system

-

Optional steel, rubber or plastic screens

-

Separate variable electronic agitation

-

Haulm roller assembly at discharge end (removes loose stalks, top etc.)

-

Hexagonal steel screens for use on onions and bulbs

-

Tuber eject roller (to remove long potatoes from the screen prior to reaching the pintle drive roller and preventing damage)

-

Separate variable electronic tuber eject or roller

-

Spacer belts to pitch grader cross conveyors to suit automatic box handling systems

-

Screen racks to store alternative screens above the module

-

Interchange facility to move module on size changes

Read More

High Angle Box Tipper

-

160° rotation to give positive emptying of boxes

-

Uprated hydraulic system giving gentle controlled flow emptying of up to 30 tip cycles per hour

-

Fully automated tipping sequence

-

Empty box ejected sideways onto awaiting platform (optional)

-

0.75 tonne holding hopper/conveyor with auto-variable flow rate to ensure smooth delivery of crop

-

Reduction in box handling prevents premature wear on boxes

-

Cross matrix light curtain safety system

-

Standard unit capable of handling up to 1.1m high boxes

-

Space saving design (ejection of empty box in same vertical plane as full)

-

Specialist models available on request (i.e. 2 tonne boxes)

-

Increased capacity holding hoppers

-

Split door facility for part emptying boxes

-

Side eject platform for empty boxes

Read More

Hydro-cooler

-

Capacities from 5tph to 30tph

-

Mild steel or stainless construction

-

Electronic variable speed drive

-

Full width modular plastic base track

-

Probe controlled infeed

-

Tailored to suit individual refrigeration equipment

-

V base tank with gate valve discharge

-

Filter system for floating debris

-

Suitable for most root crops including potatoes, carrots and parsnips

Read More

Integral De-stoner

A water weir separation system for the effective removal of stones.

-

High capacity and robust solids handling pump

-

Durable rubber chevron elevator belt to handle stones

-

Shared water supply from washer reducing overall water usage

-

Simple valve adjustment to fine tune stone removal

-

Mild steel or stainless steel construction available

-

Quick releasing door for cleaning and access to tail of elevator

-

Infeed chute available in 900mm or 1800mm wide

-

Gate valve discharge for waste water

-

Forklift tubes for ease of assembly and disassembly

-

Open impellor pump which does not require filters

Read More

Lift Roller Grader

The Herbert lift roller grader offers flexible grading for capacities from 5tph to 50tph for a range of produce.

-

High output grading for a wide range of produce

-

Capacity up to 50 tonnes per hour

-

Quiet operation due to simple design

-

Stainless steel rollers

-

Multiple grades within a compact footprint

-

Variable speed roller bed using inverter control

-

Easy adjustment of grades by simple hand jacks

-

Roller size and chain pitch to suit sizing application

-

Spool roller option for grading round produce

-

Strong and robust construction to ensure reliability and longevity

Read More

Lowerator

This versatile system is used for the very gentle and highly effective crop placement into boxes, tonne bags and bulk cartons.

-

Capacities from 5tph to 30tph

-

Gentle filling system with minimal drop

-

Effective placement of crop into boxes, bags or pro-box units

-

Automatic operation giving level fill of the container

-

Flexibility to handle various container types and sizes

-

Baseless units for use with pallet type fork trucks

-

Safe working with minimal box movements

-

Single fixed base

-

Single moving base

-

Weigh cell system can easily be added

Read More

Mechanical Clod Separator

-

95% efficient at removing clods from mids

-

Major labour saving against manual selection

-

Opportunity to sell clean mids at harvest time

-

High capacity separation with three size options

-

Belt presentation unit with fixed steel drum

-

Rotating stainless steel roller

-

Adjustable chutes for fine tuning

-

Adjustable support framework

-

Mids elevator to increase delivery height of mids sample

-

Integral conveyor for clods

-

Manual inspection table for 100% clod free sample

Read More

Oculus

Oculus identifies and sorts extremely easily and effectively for a range of surface abnormalities and diseases, including bumps and notches, skin discolouration, green and dark colours and common defects like green and mechanical damage, common scab, cracks and black dot.

-

Up to 16 images of the surface of each individual potato

-

Roller system that provides a complete 360o rotation of the tuber

-

Sorts by size, shape, colour and texture of the surface

-

Highly accurate grading for food safety defects, including rot, greens, scurf, mechanical damage and growth cracks

Read More

Pre-Soak Tank

A water hopper which prevents damage when receiving product and gives an initial cleaning/soaking action prior to delivery to the rest of the processing line.

-

Both mild and stainless steel construction available

-

A range of capacities from 5TPH to 40TPH

-

Simple gate valve for waste water discharge

-

Web delivery elevator to drain excess water

-

Integrated spray bar for fresh or recycled water rinse

-

Electronic variable speed drive to control flow rate

-

Ultrasonic sensing system to prevent overfeed

Read More

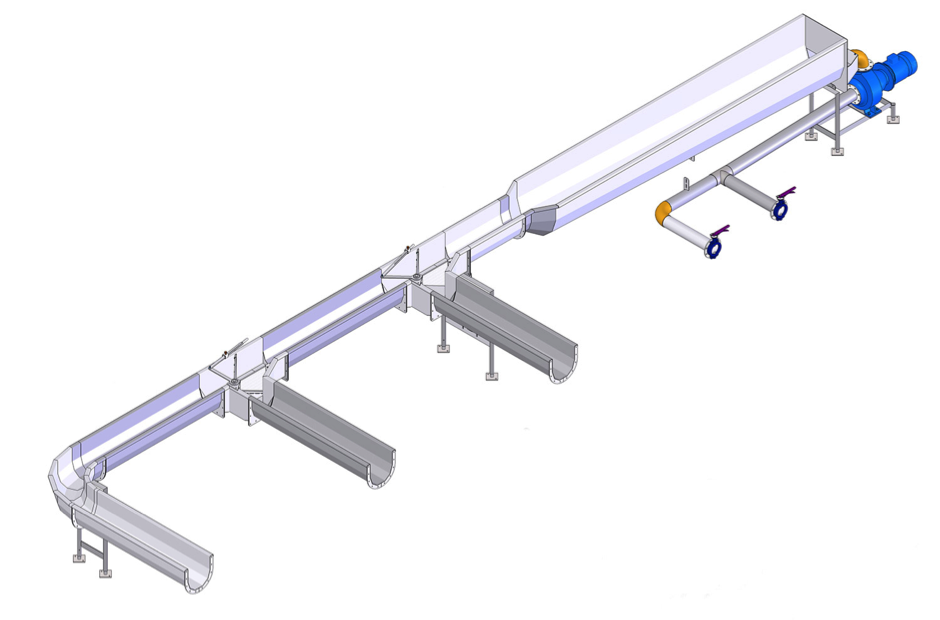

Produce Transfer Flumes

Flume designs for all applications

-

Full stainless steel construction

-

Available in a range of sizes for varying capacity

-

Manual or Automatic gate/diverter option

-

Integrated return pipework mounted beneath flume

-

Supplied as sectional flume only or fully integrated system

-

Easy sectional design to aid installation

-

Web or fixed bar de-watering options

-

Suitable for a range of products

-

Mild steel construction option

Read More

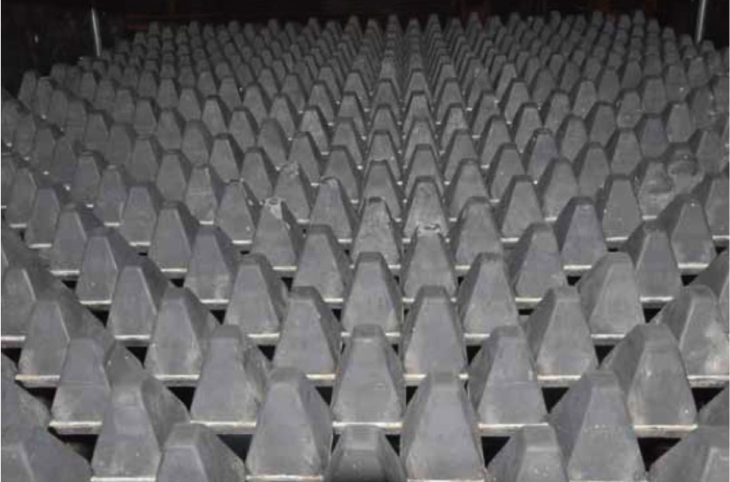

Pyramid Grading Screen

This system is available to suit all types and makes of Grader Module.

-

Accurately graded potatoes to maximise profit

-

Higher productivity from grader module

-

Less bruising and damage to potatoes

-

Average 20% improved accuracy

-

Particularly beneficial on high value salad and seed potatoes

-

Easy to maintain and repair

-

Soft rubber encourages self-cleaning

Read More

Rising Base Big Bag Filler

Gentle, effective filling of one tonne bag

-

Capacity from 5tph to 20tph

-

Hydraulic platform to raise bag for filling

-

Quick release clamp system for bag handles

-

Fully automatic pre-set controlled filling

-

Can be manufactured to suit a range of bag sizes

-

Continuous filling on twin system provides full bags replaced by empties

-

Twin or single models available

-

Safety beam system to comply with Health and Safety Regulations

Read More

Roller Drier

Effective drying of produce with unique features

-

Sponge discs for ease of replacement

-

Simple single chain drive mechanism

-

Catchment tank for waste water

-

Soft start system for drive rollers

-

Pintle de-watering roller

-

Stainless steel contact sides

-

Simple method for roller replacement

-

Hydraulic lift mechanism for maintenance and cleaning access

-

Auto lubrication system

-

Full stainless steel construction

-

15 or 20 sponge covered rollers

-

Brush rollers for stone removal

-

Direct drive to each roller

-

Felt rollers in place of sponge

-

900,1200 and 1500mm widths available

Read More

Roller Table

Continuous rotation of crop for visual selection

-

Electronic variable speed drive

-

Robust design using 7500lb heavy duty chain

-

Spring loaded rollers for simple removal

-

Friction driven system to turn rollers

-

Easy clean system for access between rollers

-

Separate variable roller spin speed

-

Blue, Grey or White roller option

-

Side chutes for rejection

-

Sealed fluorescent lighting above

-

Other pitches and roller diameters available

-

Adjustable framework and work stands to suit

-

Single or twin options

Read More

Rolling Road

Controlled filling and delivery of bulk boxes

-

Reduction in forklift usage

-

Continuous filling of boxes

-

Simple construction with easy maintenance

-

Fully enclosed by safety fence

-

Modular design for ease of installation

-

Optional turntable to orientate box

-

Automatic lift systems available for vertically stacking or unstacking boxes

-

Auto weighing of individual sizes

-

Fully computerised control, easy to programme and use

-

Can be linked to a stock control system for traceability using “tagged” or bar-coded boxes

-

Less box damage due to reduced handling

-

Automatic bar code label applicator is available as an option

-

Options automatic warehousing

-

Cooling stores

-

Track & trace

Read More

Sample Washer

Skip base design for easy emptying of waste

-

Stainless steel barrel and door

-

Compact design

-

Self-tipping skip base for easy emptying

-

Punched hole barrel design

-

Forklift tubes for ease of positioning

-

Basket in lieu of elevator

-

Solid tank base with door discharge

-

Single phase electrics

-

Variable speed drive

-

Pintle linting to barrel

Read More

Single Box Filler

The Herbert single box filler provides gentle and efficient box filling from grading and packing lines by lifting the box to almost a 90-degree angle.

-

The wide top conveyor allows for maximum fill, across the width of the box

-

Fully Category 4 light beam safety system

-

Low level discharge and consistent crop detection using ultrasonic sensors

-

High capacity output from 5 to 10TPH

-

Weigh cell systems can be easily added

-

Easy access for maintenance

-

Optional adjustable base platform to accommodate different sized boxes

Read More

Single Lowerator

This versatile system is used for the very gentle and highly effective crop placement into boxes, tonne bags and bulk cartons. The produce is carried in pockets vertically down into the receiving container and is released at the last opportunity under probe control.

-

Capacities from 5tph to 10tph

-

Gentle filling system with minimal drop

-

Effective placement of crop into boxes, bags or pro-box

-

Automatic operation giving level fill of the container

-

Flexibility to handle various container types and sizes

-

Baseless units for use with pallet type fork trucks

-

Safe working with minimal box movements

-

Twin model option

-

Moving base

-

Weigh cell system can easily be added

Read More

Star Cleaner

Efficient separation of clods and soil from produce

-

7 rows of 14 fingered polyurethane star wheels

-

50mm square drive shafts

-

Adjustable gap on first 3 rows of stars for heavy lifting conditions

-

Reversible clod roller with scraper

-

Easy vertical and horizontal adjustment of clod roller by simple lever mechanism

-

Variable speed star drive

-

Separate variable speed clod roller

-

Heavy duty chain mechanism

-

Heavy duty chain mechanism

Read More

Twin Box Filler

The GF2 box filler delivers fast and efficient box filling from grading lines and self-unloading vehicles.

-

The wide top conveyor allows for improved ll, across the width of the box

-

Static box position provides safer operation

-

Low level discharge and consistent crop detection using self-adjusting sensors

-

Continuous filling operation with no interruption

-

High capacity output from 5 to 50TPH

-

Easy box pick up from oor with baseless design

-

Weigh cell systems can be easily added

-

Easy access for maintenance

-

Optional adjustable base platform to accommodate different sized boxes

Read More

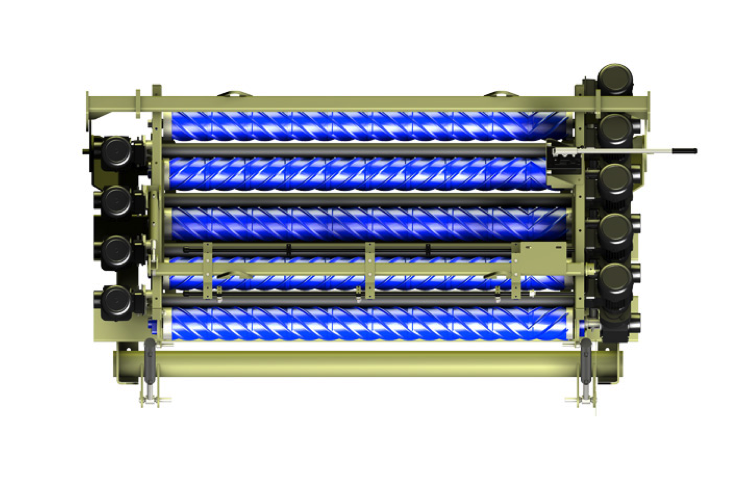

Variclean

Designed to work with all of Herbert grading systems, or as a standalone machine, the Variclean incorporates the very latest in technological developments that combine improved cleaning of crops, gentler handling and low maintenance.

-

Herbert intelligent control system

-

Graphic display for easy and clear setting/adjustment

-

Interchange modular design

-

Choice of spiral roller flight heights

-

Automated “stuck item” clearing system on clod rollers

-

Individual roller drives for maximum flexibility and control

-

Angle adjustable module providing variable cleaning effect

-

Robust build for heavy conditions

-

Hydraulic driven system

-

Optional machine widths of 900, 1200, 1800 and 2400mm

Read More

Vector

The Herbert Vector grading module is the result of extensive research and development to improve the performance and accuracy of screen sizing particularly when working with larger mesh screens and long tuber varieties.

-

Suitable for potatoes, onions, bulbs and red beet

-

Long tuber ejection as standard

-

Independent inverter drives to both screen and agitator.

-

New design for quick and easy screen changes

-

High capacity accurate crop sizing

-

No impact damage

-

Robust and simple construction

-

Direct replacement into most existing Herbert grading lines

-

Brush section rollers for Onions

-

Spacer belts to pitch grader cross conveyors to suit other equipment

-

Screen racks to store alternative screens above the module

-

Interchange facility to move module sideways on repetitive screen changes

Read More

Vertical Eject Box Tipper

The Herbert Vertical Eject Box Tipper is a proven best-seller for several years and continuous development has produced a safe, gentle yet highly efficient method of emptying boxes.

-

High capacity of 24 cycles per hour

-

Full clamp facility to prevent spillage

-

Hydraulic door for gentle produce flow

-

Category 4 safety beam system

-

Large holding hopper/conveyor with auto speed control

-

Designed to accommodate a range of box sizes (3’0” to 3’8”)

-

Version for extra-large boxes (3’8” to 4’0”) is available

-

Hydraulic rubber hose kit assembly

Read More

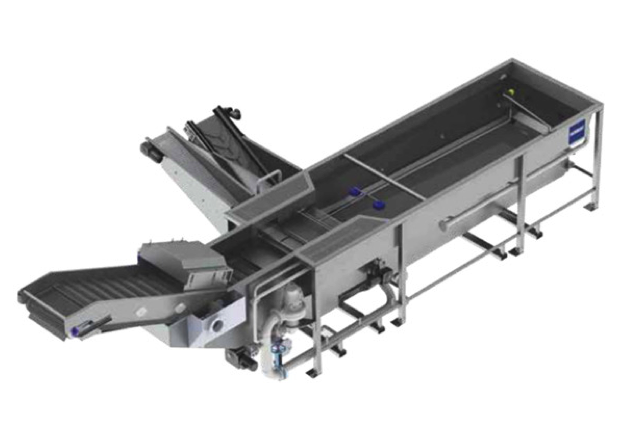

Wet Reception Hopper

The wet reception hopper system is more than just a pre-soak tank and has additional features and functionality which sets it apart from the competition.

-

A capacity range from 5TPH per hour to 50TPH per hour

-

Driven auger base to tank Elevator Belt

-

Effective stone separation area

-

Web delivery elevator to drain excess water

-

Integrated spray bar for fresh or recycled water rinse

-

Sensing system to prevent overfeed

-

Durable rubber chevron de-stoner elevator belt to handle stones

-

Floating object removal system

-

Simple pneumatic gate valve for waste water discharge

-

Sludge scraper/drag chain system to remove “solid” waste

-

Extended tank for side delivery

-

Electronic variable speed drive to control flow rate from elevator

-

Both mild and stainless steel construction available

Read More

Wetting Unit

Simple method of re-wetting produce prior to packing

-

Fixed speed drive

-

Sponge disc rollers

-

Simple chain drive system

-

Auto tensioning

-

Stainless steel construction

-

Catchment tray for excess water

-

Rinse bars with hoods

-

Easy access hinged guard work

-

900, 1200 & 1500mm widths

-

900, 1200 & 1500mm widths

Read More